With its roots dating back to 1945, Darbagos was focused on the production of wooden parts for religious buildings, churches and their interiors - pulpits, stairs, choir lofts and other wooden elements. In addition, the company had its own quarry, the material from which was used to make the foundations of buildings. In subsequent years its activities were expanded to include transport services. Darbagos' most recent activity dates back to 1993. With time, the one-person business entity was transformed into a commercial company. The company focused on providing specialist demolition and earthmoving services and selling aggregates, including recycled ones.

As a consequence of further development, the company has broadened the scope of its activities, focusing on services in the field of execution, modernisation and repairs of process devices and structures for customers representing various branches of industry: chemical, food, petrochemical, power, machinery, etc.

The recipients of our products include: Grupa Azoty S.A. in Tarnów, Polskie Konsorcjum Chemiczne Grupa Azoty S.A., ZWRI Sp. z o.o. Sp. K., Taskoprojekt S.A., Acero System Sp. z o.o., EC Engineering Sp. z o.o., Bruk-Bet Sp. z o.o. and others.

Our production offer includes, among others: pressure and low pressure vessels, shell and tube heat exchangers, steam and water boilers, columns, reactors, mixers, technological and transmission pipelines, construction steel structures and machine elements, etc.

In order to meet market demands, Darbagos has recently completed large-scale investments related to securing proper infrastructure for the implementation of production activities. Two production halls were built and equipped with modern machinery and tools. The current machine park enables us to provide services in the field of large-size machining, welding services, hydro-abrasive water jet cutting of steel elements and manufacturing of pressure and non-pressure equipment elements. The company employs experienced staff (supervisors, technologists and equipment operators, welders and fitters) who participate in the production process. As a specialist company we execute orders on the basis of entrusted technical documentation, but in cooperation with our experienced designers we are able to offer comprehensive execution including preparation of required documentation according to the regulations: WUDT/UC/2003, PN-EN 13445, ASME.

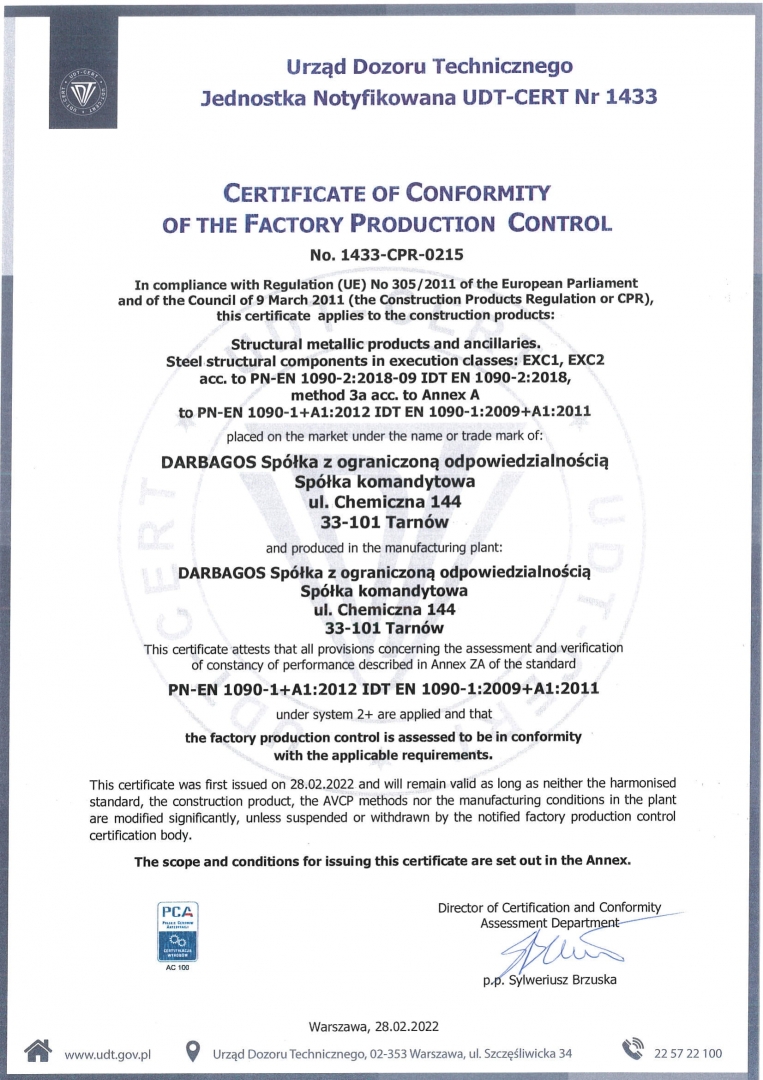

CERTIFICATE

In order to meet customer requirements, the plant has prepared and implemented:

• Quality Management System in accordance with ISO 9001:2015 - certified by UDT CERT.

• Certificate verified in accordance with PN-EN ISO 3834-2 standard confirming compliance with the quality requirements in welding processes

• Certified Factory Production Control System compliant with the EN 1090-1 standard set

We are a company authorised by the Office of Technical Inspection to manufacture pressure components and carry out modernisation and repairs of:

• Steam and water boilers,

• Non-pressure and low-pressure vessels for poisonous, corrosive and flammable liquids,

• Steam pipelines connecting the boiler to the turbine generator,

• Process and transfer pipelines for flammable, poisonous and corrosive materials,

• Fixed pressure vessels

The scope of our authorisations granted by the Office of Technical Inspection also includes repair and modernisation of lifting equipment such as: cranes, mobile platforms, overhead travelling cranes, stacker cranes, equipment for the disabled, trolleys, hoists, winches, mobile and transportable cranes, truck cranes and stationary cranes.

The technical level of knowledge of the management, technological and welding personnel as well as of the staff of the production department is constantly verified by our customers and confirmed by training courses and certificates of the Office of Technical Inspection.

Satisfaction of our customers from all over Poland is a confirmation of our professional and individual approach to every task. Possession of specialist equipment combined with knowledge and rich experience of our staff guarantee high quality of services provided by Darbagos.